Technology

Engineering For Precision. Built to Last.

Engineering Precision

The 12-Stage Manufacturing Process

Material Selection & Traceability

Only certified brass, stainless steel, and aluminium are used, with each batch tested and tracked through heat-lot traceability.

Raw Material Selection & Forging

Incoming materials are verified for chemical composition, hardness, and mechanical strength, ensuring compatibility with specialty and calibration gases.

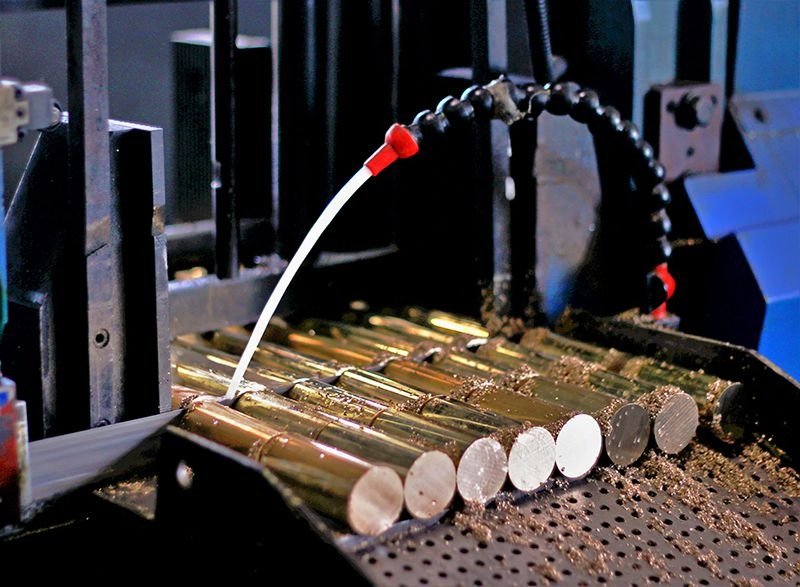

Precision Machining (CNC/VMC)

Critical components are produced on CNC turning centers and VMC machines, maintaining tight tolerances for threads, sealing faces, and flow passages.

In-Process Quality Checks (SPC)

Statistical Process Control (SPC) checks are performed at machining stations, ensuring consistency across high-volume runs and custom parts.

Surface Finishing & Cleaning

Components are deburred, polished, and cleaned in controlled conditions to remove machining residues — essential for leak-tight gas service.

Sub-Assembly Preparation

Parts are organized into clean assembly cells, with torque/thread control applied to avoid damage and ensure proper sealing.

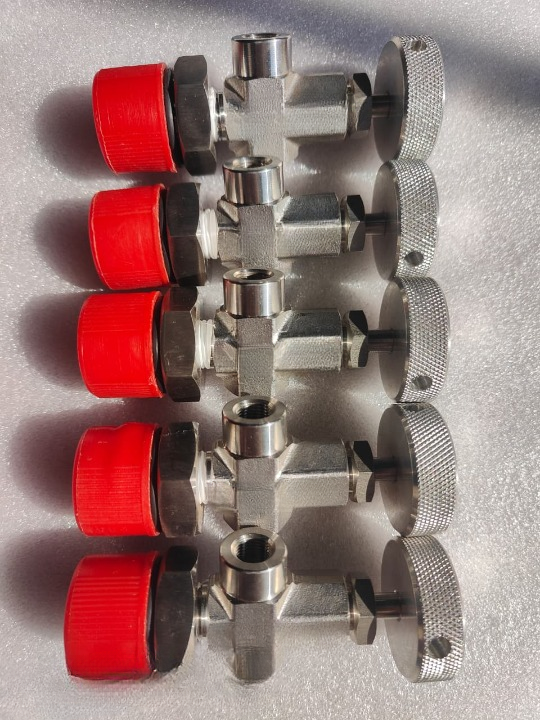

Assembly of Valves & Regulators

Technicians assemble valves, regulators, and flowmeters using calibrated tools. Clean benches prevent contamination of sensitive sealing components.

Pressure & Leak Testing

Each unit undergoes hydrostatic (up to 15,000 psi), nitrogen leak, and pneumatic tests to guarantee leak-tight performance.

Functional & Flow Verification

Regulators and flowmeters are tested for flow accuracy, repeatability, and stability across setpoints, ensuring calibration-grade reliability.

Proof & Burst Testing

Random samples undergo destructive testing, including burst and proof pressure tests, validating product safety under extreme conditions.

Final Inspection & Documentation

Every product receives dimensional checks, visual inspection, and performance validation. Inspection records and compliance certificates are supplied on request.

Safe Packaging & Export Readiness

Products are packed in eco-friendly, CFC-free protective trays with full export documentation (COC, test reports, HS codes) — ensuring safe delivery worldwide.