Prototyping & Services

Prototyping & Product Development Services

At Oxford Valves, we specialize in end-to-end custom development of valves, regulators, and gas control assemblies. From early-stage design to rapid prototyping and production, we help transform ideas into precision-engineered, reliable products.

Design Engineering

Our engineering team partners with you to design high-performance solutions that are functional, durable, and production-ready.

Capabilities:

- Technical consultation & feasibility analysis

- CAD modeling and drawing preparation

- Materials and flow control selection

- Product optimization for safety & reliability

Product Development

From concept to small-batch production, we deliver solutions tailored to your specific requirements and application environments.

What we offer:

- Custom valve & flow control components

- Design support for OEM integrations

- Revision engineering & upgrades

- Application-specific functionality

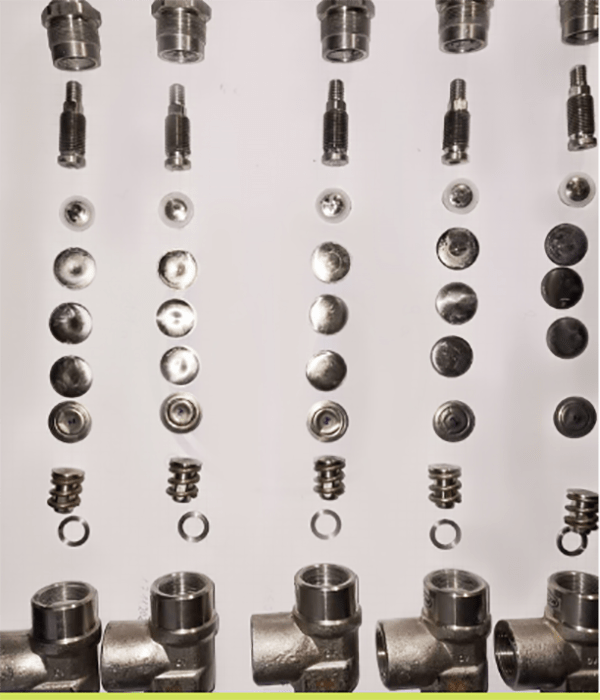

Prototyping

Using cutting-edge CAD software and our in-house tool room, we provide rapid prototyping to accelerate your product development.

Benefits:

- Validate product fit and function

- Speed up design iterations

- Shorten time-to-market

- Test and refine concepts quickly

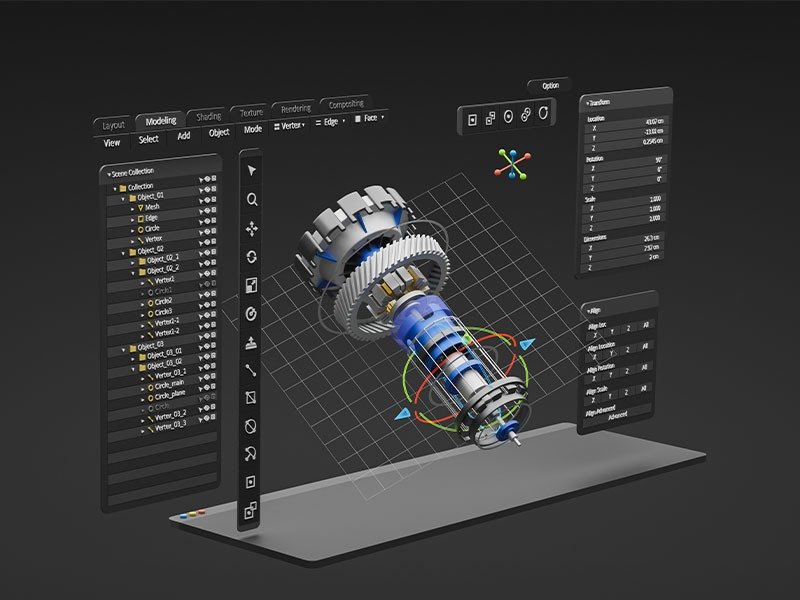

3D Modeling

We leverage advanced 3D modeling tools to ensure accurate prototyping and seamless design iterations.

Advantages:

- Simulate product performance before production

- Enhance client communication with visual models

- Reduce errors and rework

Facilitate cross-functional design reviews

Precision Manufacturing & Tool Room

Our state-of-the-art production facility in India is designed for precision manufacturing with international clients in mind.

• CNC Turning Centers – fully equipped units for high-accuracy machining.

• VMC Machining Centers – advanced centers for complex geometries.

• Supporting Equipment – Bandsaw, drilling machines, tool setting station.

• Hydraulic Presses – Two presses for forming and endurance.

• Assembly & Testing – Dedicated clean assembly benches with torque/thread control, complemented by custom-built test benches for final product validation.

Let’s Build Your Solution

Whether you need a one-off prototype, a custom-engineered valve, or full product lifecycle support — Oxford Valves is your development partner.